Add to Cart

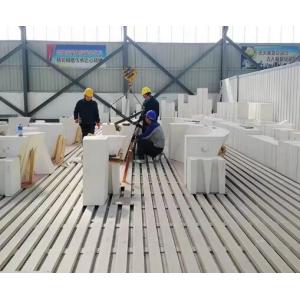

The size is precise, providing kinds of shapes according to customer's drawing

Product Details

1.Corundum Brick contain more than 90% of aluminum oxide that have another name is alumina oxide bricks.

2.Corundum brick is manufactured using high quality synthetic electro-fused corundum and sintered corundum and finely grained highly alumina raw materials with ceramic and chemical bonding.

3.This brick is shipped under high pressure and fire with high temperature with scientifically and reasonably gradating and adding good performance of additives.

Product Feature

1.High temperature resistance

2.High strength,high compression resistance,

3.Excellent thermal shock resistance,

4.High bulk density, good thermal conductivity,

5.Good wear resistance and acid,alkali corrosion resistance.

Product Applications

Corundum Bricks are mainly used in the linings in decomposing furnaces for petroleum and chemical industry, as well as the chemical fertilizer industry. They are also used as high temperature kiln linings and furnitures in metallurgical industry.

Physical and chemical indexes

| chemical composition | AZS-33 | AZS-36 | AZS-41 | |

| ZrO2 | ≥33 | ≥35 | ≥40 | |

| SiO2 | ≤16.0 | ≤14 | ≤13.0 | |

| Al2O3 | a little | a little | a little | |

| Na2O | ≤1.5 | ≤1.6 | ≤1.3 | |

| Fe2O3+TiO2 | ≤0.3 | ≤0.3 | ≤0.3 | |

| Physical Properties | AZS-33 | AZS-36 | AZS-41 | |

| bulk density(g/cm3) | 3.5-3.6 | 3.75 | 3.9 | |

| cold crushing Mpa | 350 | 350 | 350 | |

| thermal expansion coefficient (1000°C) | 0.80 | 0.80 | 0.80 | |

| exudation temp. of glass phase | 1400 | 1400 | 1400 | |

| corrocion resistance of glass melt(mm/24h) | 1.6 | 1.5 | 1.3 | |

| Density | PT QX | 3.40 | 3.45 | 3.55 |

| WS ZWS | 3.60 | 3.70 | 3.80 | |

| phase composition(%) | AZS-33 | AZS-36 | AZS-41 | |

| baddeleyite | 32 | 35 | 40 | |

| glass phase | 21 | 18 | 17 | |

| α- corundum | 47 | 47 | 43 | |